Upright design improvement for 300kg atv (Design for 3 axis CNC manufacturing)

2019-2020 upright

Designed for the first time, 2020 upright was never designed according to the manufacturer’s machine specs. In order to complete the job, manufacturer outsourced the machining of the uprights which further delayed the delivery date and increased the overall cost of the upright. Also, the upright was overdesigned with a safety factor of 6 and required a large block of AL 7075 T6 which was indeed expensive.

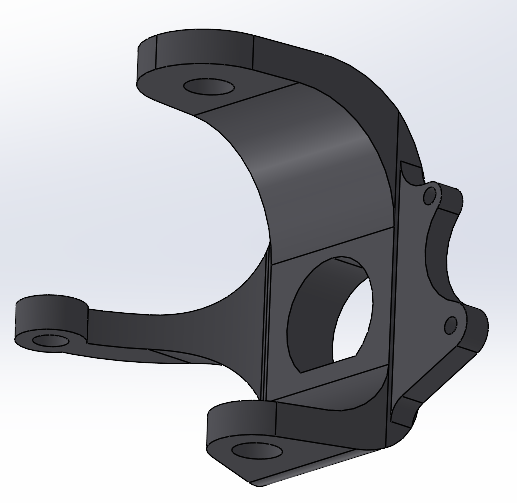

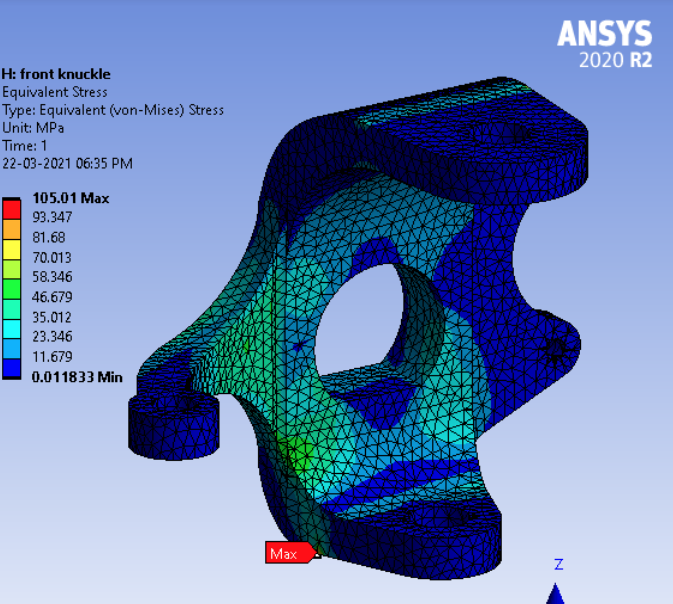

2020-2021 upright

Evaluating previous years performance, prime objective of this year was to reduce the overall raw material required to machine the upright. To achieve the same, upright wall height was reduced and entire suspension geometry was redesigned. Upright was designed considering the capabilities of the milling machine and thus the team was able to achieve 25% weight reduction on the finished upright and 20% overall cost reduction when compared to 2020 uprights while being under the safety limits.

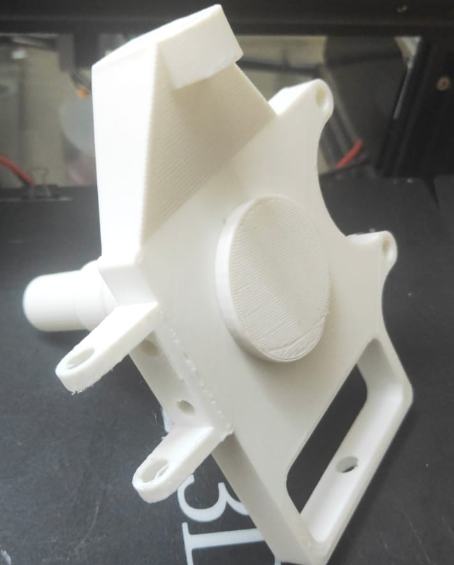

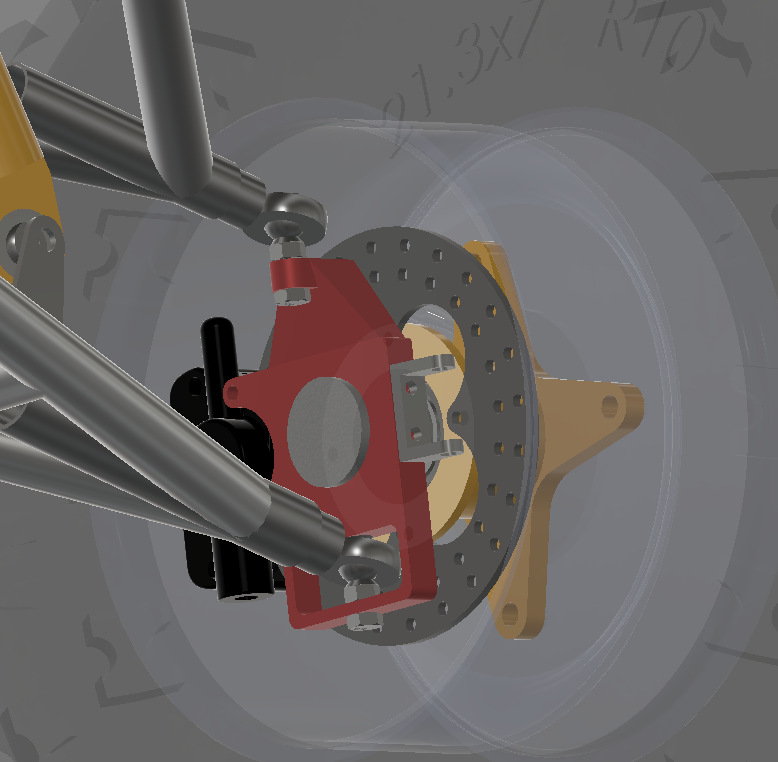

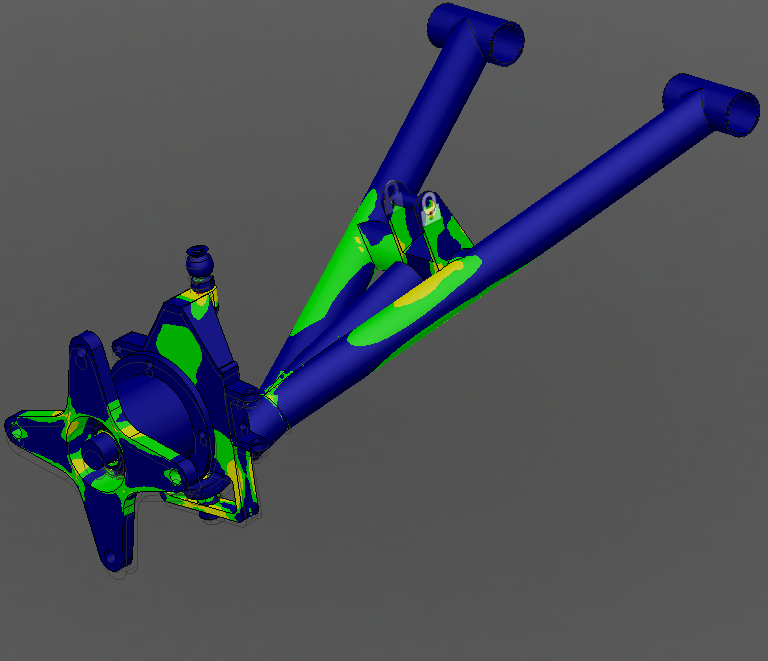

2021-2022 upright

While working on the 2021 upright design, 2022 upright was conceptualised. 2022 upright is a complete redesign over 2020 and 2021 uprights. In order to achieve such a form factor kingpin axis was provided along the vehicle X-axis which allowed the lower ball joint point to be incorporated in the upright wall. furthermore, the steering arm was made modular to further reduce the volume of the raw material block to reduce overall machining costs. ultimately 50% cost and weight reduction were achieved when compared with 2020 and 2021 counterparts while achieving a safety factor of 3.5.