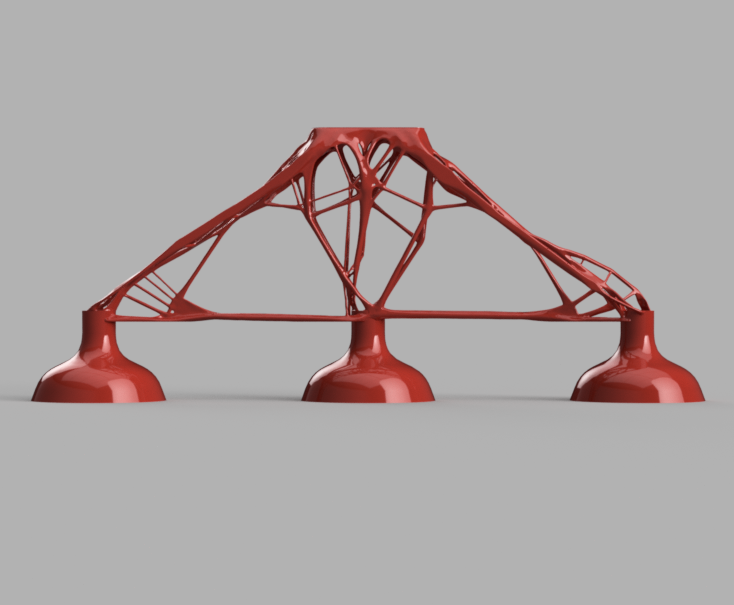

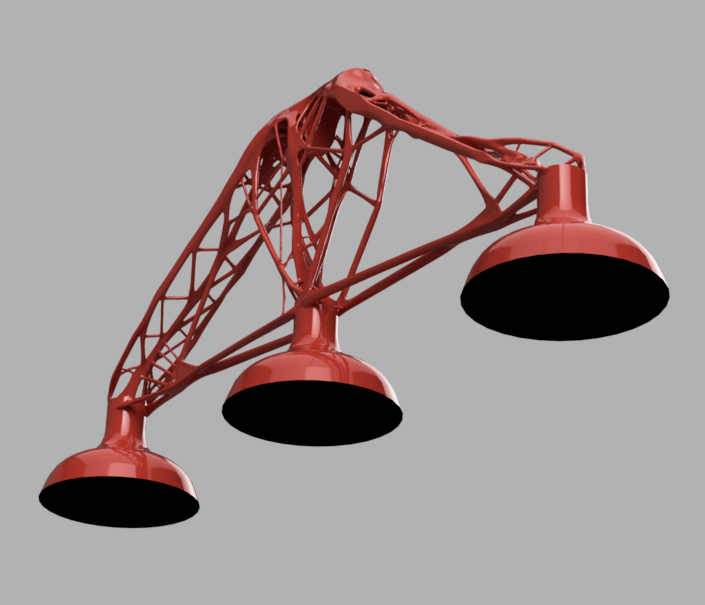

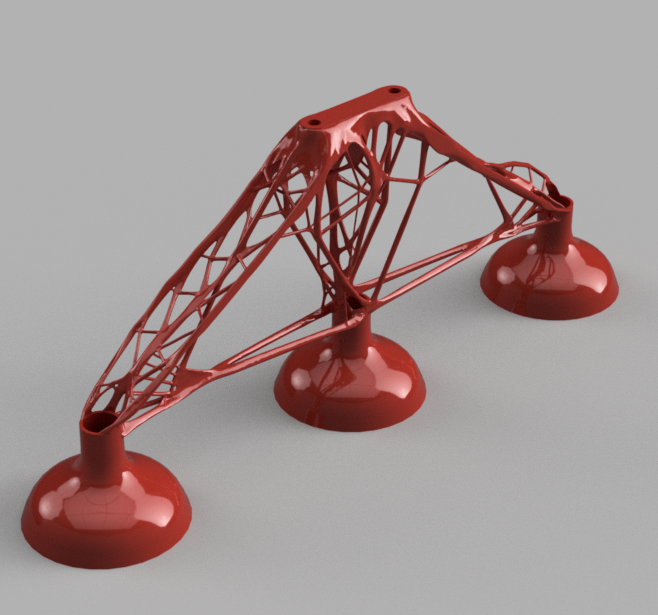

Lamp Fixture designed with Generative modelling

Generative design often comes later in the design process after something has been created, but in some cases, you can insert generative design very early in the design and exploration process opening up new potential options. This was one example of this. A new light fixture is being explored. The only aspects of the design that are fixed are the number of lights, their location and distance from the ceiling mount. How the lights attach, and the overall design hasn’t been considered yet. The challenge was to set up, run and post-process a light fixture for consideration. There were some basic parameters and suggestions but everything else from material, manufacturing methods and even loads was at my discretion. The following information is provided: Each lamp shade, fixture and bulb can weigh as much as 20 lbs. Load cases: Force of a light bulb change. force of bumping into the light. force of cleaning/dusting the light. Additional forces? When considering the attachment for the lamp shades, common fixtures and how they attach were considered. Some have a threaded feature around the light fixture, some use set screws into a shade. Final choice for outcome as chosen based on additive manufacturing method.

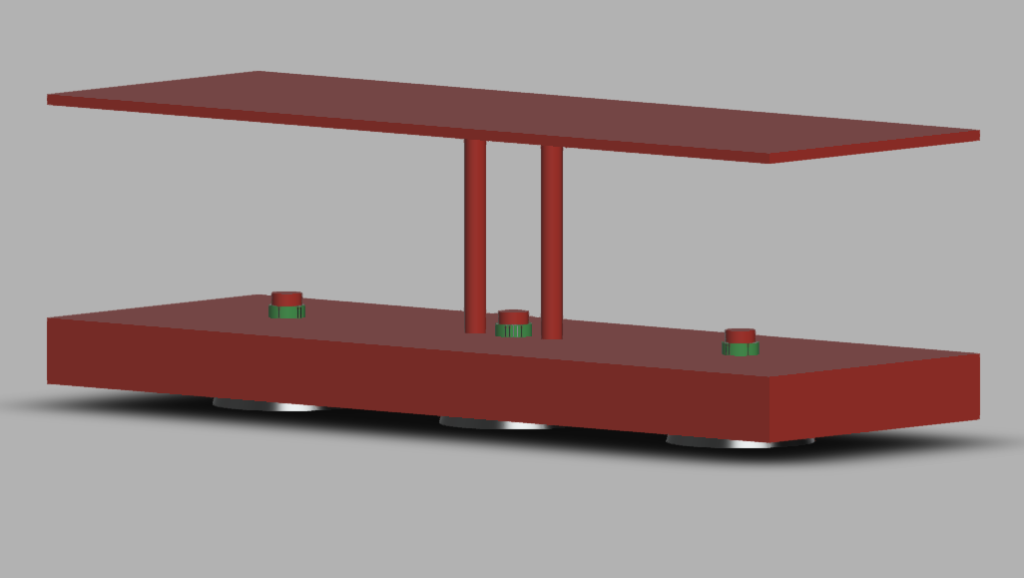

Preserve and obstacle geometry configuration

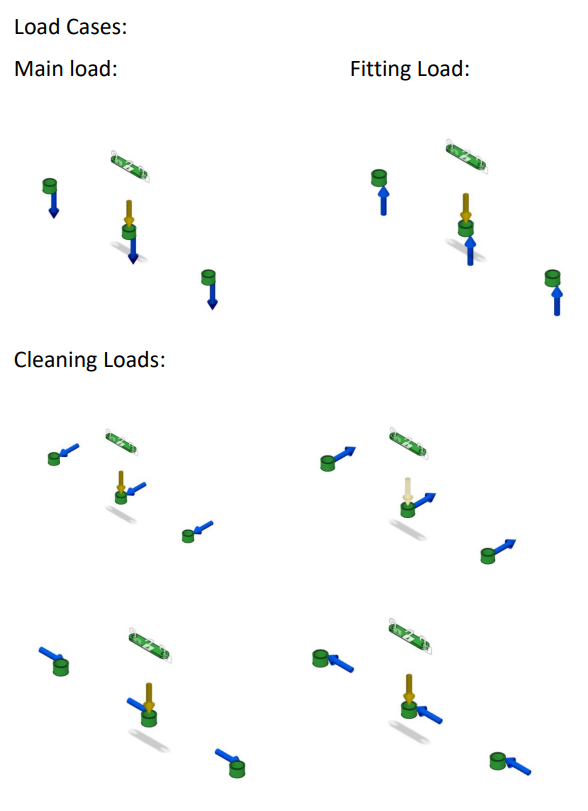

Load cases